Pulse compression gratings for demanding high-power ultrashort pulse laser applications

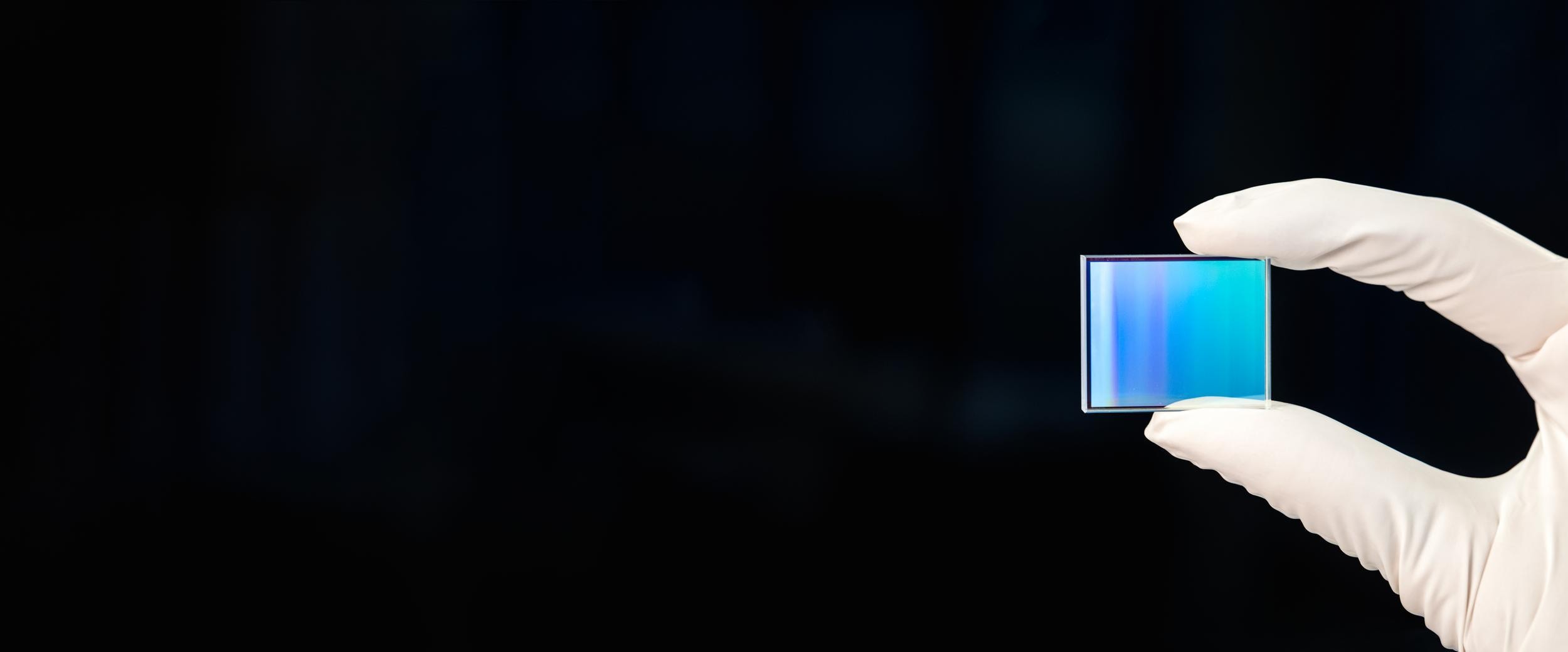

Jenoptik´s dielectric e²® pulse compression gratings are highly efficient and durable under high laser power densities. They are made of high-purity fused silica and are thus well suited for a broad wavelength range – in transmission or reflection.

Whether reflective or transmission pulse compression gratings, our PCGs offer high diffraction efficiency, low wavefront errors, and a high laser-induced damage threshold. Thanks to their embedded grating structure the transmission e²®- PCGs are also protected from external mechanical damage and dust.

Discover how our PCGs increase efficency, performance and reliablity for the following applications

- Laser pulse compression in chirped pulse amplifiers (CPA)

- Spectral beam combining of high-power laser for laser material processing

- Wavelength selection and bandwidth narrowing

- Spectral beam combining

Key facts to know about diffraction gratings

A diffraction grating’s performance is governed by a handful of inter‑related properties. Understanding which ones matter most for your application will help you choose (or design) the right grating.

Key Advantages

Highly efficient

Maximum diffraction efficiency, close to 100%, to enhances the performance of your laser

High line densities

(up to 5000 ln/mm), enable compact product design and high pulse compression

High dispersion

Better spectral resolution allowing high-precision and sensitivity

High damage threshold

Encapsulated fused silica gratings with both sides excellent dielectric AR coating system (for transmission)

Customer-specific design

Choose dimension up to 140 mm square and line densities up to 5000 lines/mm

Check out our reflective PCGs for high-power and high-dispersion pulse compression!

High-quality manufacturing for customized gratings

Jenoptik offers customized pulse compression grating solutions that are precisely engineered to meet each customer's specific requirements. With a variety of options available, such as different grating periods, sizes and coatings, customers can rely on Jenoptik to provide a bespoke solution that meets their exact requirements.Our state-of-the-art manufacturing facility in Dresden, equipped with the latest technology and equipment, enables us to produce high-quality, customized gratings with unparalleled precision and accuracy.

Benefit from the newest facility features

Advanced lithography tools: Jenoptik has installed advanced lithography tools, including electron beam lithography to enable the production of high-precision gratings with complex patterns.

Automated manufacturing lines: Jenoptik has implemented automated manufacturing lines to ensure high throughput and consistent quality, while minimizing the risk of human error.

Take advantage of our broad product portfolio to obtain a suitable complete solution from a single source